THE FOUR DIMENSIONS OF COMPETITIVENESS

Becoming digital, efficient, sustainable, and resilient all at once is a major challenge for many companies today.

However, the Staufen “Future Industry” study shows that boards and management teams in industry have clearly set their strategic compass. The foundation for a sustainable, change-ready and resilient business is and will remain operational and digital excellence. When set up in this way, a multi-faceted challenge for a company can become a multi-faceted opportunity.

ABOUT THE STUDY

For the “Future Industry” study, Staufen AG surveyed more than 400 industrial companies in Germany, Austria, and Switzerland in the first quarter of 2023.

DIGITALIZATION REMAINS THE NUMBER ONE ISSUE FOR THE INDUSTRY

When it comes to digitalization, it’s no longer a question of if – it’s only a question of how. The majority of companies still answer this question for themselves with measures to increase efficiency.

key-Insights

- Current economic developments continue to drive digitalization.

- Lean Management makes companies efficient and fit for the future.

- One in two companies is still struggling to determine its footprint.

- Four out of ten companies now only award contracts to green suppliers.

- A resilient supply chain network: Digitalizing processes is a priority.

LEAN MANAGEMENT AS A SOLID FOUNDATION

Lean Management is a very effective lever for companies to reduce costs, achieve their own growth goals, and improve their competitive capability in the long run. A cooperative leadership style and goal-oriented communication are indispensable here.

However, many companies are still leaving a lot of lean potential untapped on the road to efficient value creation.

SUPPLY CHAIN NETWORKS WITH POTENTIAL

Since the painful experiences of the past few years of multiple crises, it has become clear that the supply chain networks of the vast majority of companies still have a great deal of efficiency potential. In order to survive in the face of international competition, it is essential to raise the level of communication with customers and suppliers to a new level – for example, with the help of digitalization.

However, many organizations have yet to take full advantage of digital opportunities.

WE LEARN IN THESE CRISES THAT TAKING A LONG LOOK BACK IS NOT VERY SUCCESSFUL. INSTEAD, CHANGE SHOULD BE DRIVEN BY RAPID ADAPTATION.

Michael Glieden

Vice President Production & Supply Chain, SCHOTTEL GmbH

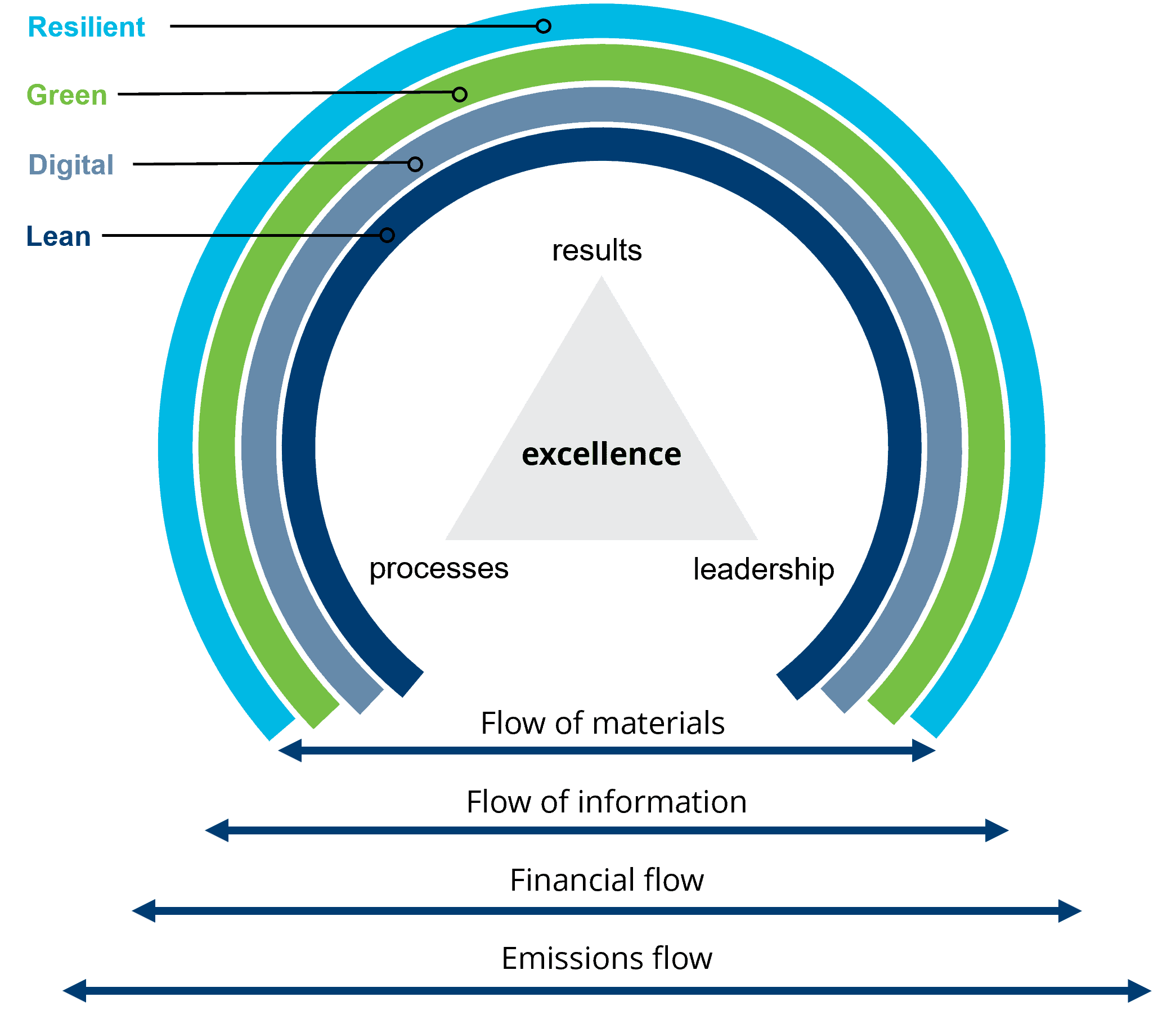

HOLISTIC DESIGN OF END-TO-END PROCESS EXCELLENCE

THE FOUR ELEMENTS LEAN, DIGITAL, GREEN, AND RESILIENCE

The framework provides a sensible regulatory framework that helps companies set the right priorities to remain competitive in the future. The figure introduces our holistic approach to consulting and shows the wide range of topics where and how we can support our customers. The focus is on our mission: excellent processes, excellent leadership, and, as a result, excellent results. The four elements Lean, Digital, Green and Resilient play a central role as both drivers and tools for optimally configured end-to-end processes.

HAVE QUESTIONS? CONTACT US!

We hope that this study will provide you with some valuable ideas on how your company can successfully continue on this path, and we look forward to speaking with you.

SCNM

Canan Jungel

Practice Lead of SCNM

STAUFEN.AG

Phone: '+49 7024 8056 0

E-Mail: canan.jungel@staufen.ag

Canan Jungel

Practice Lead of SCNMSTAUFEN.AG

CURRENT AND FUTURE TRAININGS OF THIS TRAINER

III. Train-the-Trainer to become a lean trainer

Operational Excellence in SME | Albrecht Jung live

Material in flow | SEW-EURODRIVE live

II. Lean Logistics

I. Basic training as a Lean Expert

Canan Jungel was during her dual bachelor studies as an executive assistant for the international freight forwarding company Gerner + Kahle GmbH responsible for operational logistics improvements. As a master‘s degree candidate Canan Jungel contributed to the development and introduction of the Lean Logistics Seminar for Staufen Academy. Since 2014 Canan Jungel is working as an Lean Consultant and Trainer at the Staufen AG. Since then she is nationally and internationally implementing lean transformation projects with the focus for lean processes and lean logistics operations. Furthermore as a Coach she is implementing and stabilizing Shop Floor Management in various branches. Within the Staufen Academy she is responsible for trainings within the public program, internal qualification and international training standards. Besides that she designs and conducts successfully customer specific qualification and training programs.

REQUEST THE STUDY AS a DIGITAL VERSION NOW