Böllhoff is the competence leader in fastening technology. Marcel Rupprecht, Managing Director responsible for the Group’s European retail business, explains in an interview how Lean Management is practiced at the company and what role managers play in it.

Böllhoff is a global partner for 360° fastening technology with assembly and logistics solutions. Family-run since 1877, the company stands for long-term success through innovative strength and customer proximity. As a fastening specialist, Böllhoff knows the specific requirements of its customers from all industries and supports them in creating successful connections. More than 3,300 employees at the headquarters in Bielefeld and in the worldwide group of companies are shaping the future of fastening technology. In 2022, Böllhoff achieved sales of approximately 783 million euros.

An expert contribution to the 2023 “Future Industry” study

Interview with Marcel Rupprecht, Böllhoff GmbH

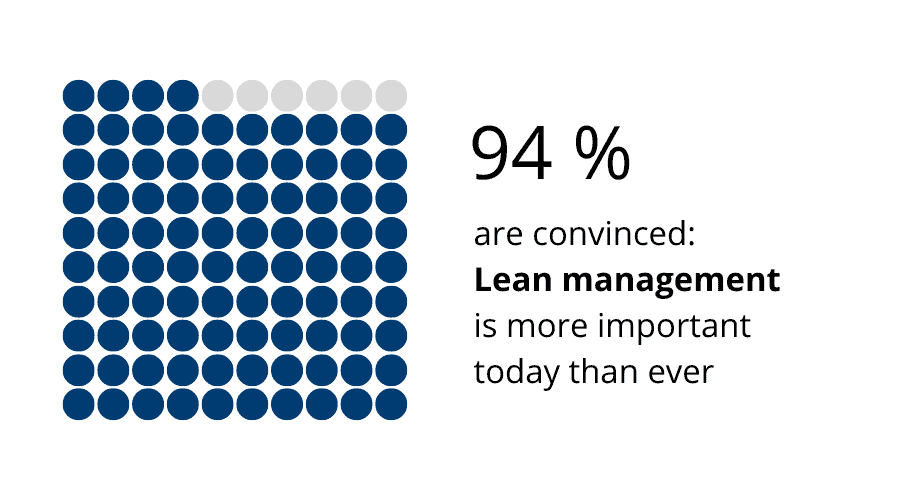

94 percent of companies surveyed for the Staufen study see Lean Management as a solution to today’s challenges. Do you agree with this assessment?

Marcel Rupprecht: Yes, because when applied correctly, Lean Management helps companies work more efficiently and position themselves for the future. Customer focus is at the heart of everything we think and do. At the same time, the aim is to implement efficiency improvements at all levels of the company. As a management tool, Lean Management is adaptable and, most importantly, it creates value.

Does lean management help to overcome current challenges?

Is Lean Management used throughout your company?

Marcel Rupprecht: At Böllhoff, we have been working with Lean Management methods in the production areas for a long time and also use them in accordance with our corporate strategy. What is new for us is the use in the administrative area. This is how we break down silo thinking of individual departments. We replace it with a holistic, end-to-end process. The result of this new way of thinking about processes: more involvement in the big picture, fewer complaints, greater satisfaction for all involved, and lower costs.

Where does Böllhoff stand today in terms of lean maturity?

Marcel Rupprecht: Overall, we consider our maturity level to be high. But we are not resting on our laurels, we are constantly working to improve. The goal is to optimally coordinate all activities necessary to create value and eliminate waste. We do this by reviewing and improving the existing system from two perspectives: the customer’s perspective and the company’s perspective. For customers, we work to optimize availability, quality, individuality and pricing. From a business perspective, it is about sustainability and continuously improving competitiveness.

What does this mean for day-to-day operations?

Marcel Rupprecht: Lean makes our lives easier. We no longer sit in meetings and set new agendas, but work in a goal-oriented manner. In the 30-minute regular communications we introduced across all teams, we focus on the three topics important to us: deviation management, incident management, and information and task management.

Does this also work across departments?

Marcel Rupprecht: Absolutely. A practical example from our service and trading business: In the past, our many, many customer requests were passed from department to department and processed with too little filtering. In line with our Lean principles of “focused, excellent, creates value,” we are now very careful not to get lost in the details, but to examine inquiries much earlier to see whether they really are optimally suited for quotation in terms of application technology, logistics and business. In this way, we avoid long – and often useless – internal and external process loops. As a result, we have increased the success rate by better qualifying inquiries while improving effectiveness. In short, by asking the right questions from the start, we reduce effort and increase quality – for the ultimate perfect connection for and with our customers.

The Staufen study shows: Value creation efficiency and leadership excellence are closely linked. Where do leaders still need the most training?

Marcel Rupprecht: Leadership excellence and employee empowerment remain the most important issues. This includes a collaborative leadership style with empathy, courtesy and respect for each individual, active ownership and passion – in everything we do. We have always made sure that our managers in the teams have a hands-on mentality. In order to recognize and develop potential, it is important to qualify and guide employees. Last but not least: Training in targeted communication! Without targeted communication, no one knows where the journey is going.

More About Operational Excellence

“Good risk management empowers employees to make more independent decisions”

Zurich-based drone specialist Wingtra impresses with enormous growth rates. A smoothly functioning supply chain network is essential. COO Marco Schicker explains in an interview how Wingtra interacts with customers and suppliers and why risk management does not restrict but creates freedom.

Read more

Study: Future Industry

How the industry is positioning itself for the future! Our new study on the topics of digitalization, efficiency, sustainability and resilience.

Read more